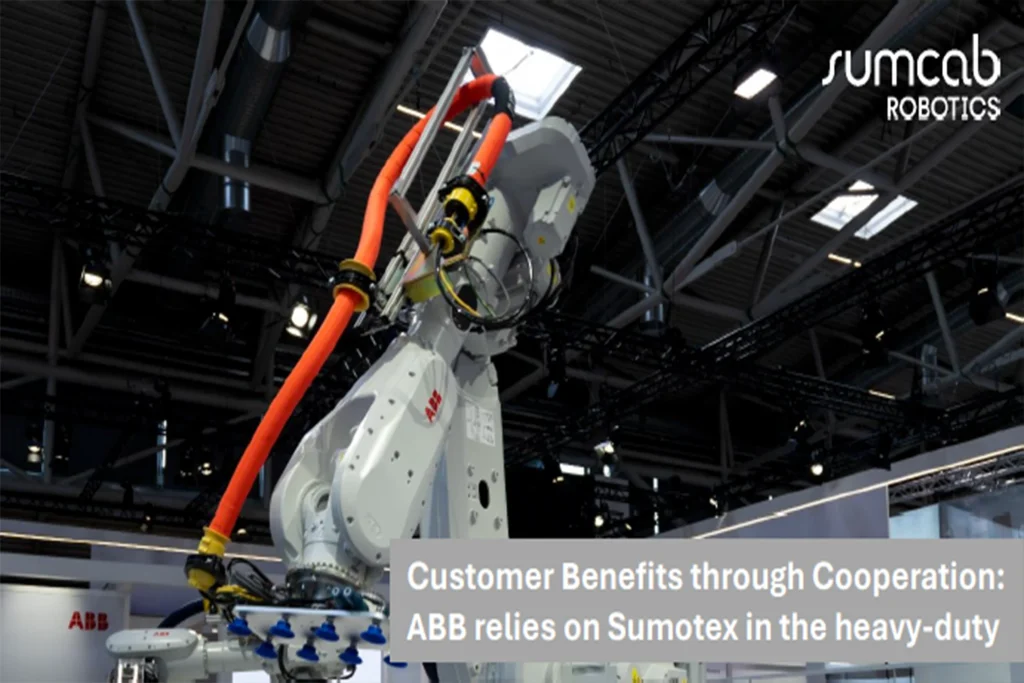

The heavy-duty IRB 6750S robot is shown in a combined system for handling and spot welding. For reliable energy and media supply to both robots, Dresspacks from Sumcab Robotics were used.

Heavy-duty robots require flexibility and performance

In many manufacturing processes, heavy components must be moved, positioned, or welded—often under tight space constraints and with high demands for reach and accuracy.

Heavy-duty robots are designed precisely for these tasks: they combine high payloads with stable kinematics, enabling automated workflows in areas such as automotive production, body construction, or general metalworking.

A good example is ABB’s newly introduced IRB 6750S. This robot combines a high payload capacity of up to 350 kg with a horizontally offset first axis. This design allows for more compact cell layouts and better utilization of the workspace, particularly in systems with limited space.

Figure 1: ABB heavy-duty robot IRB 6750S with Sumotex at Automatica 2025

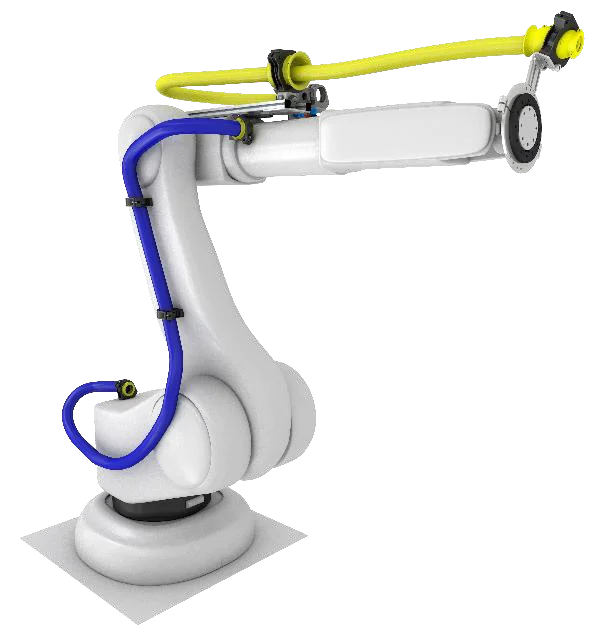

Figure 2: Sumotex – flexible cable management solution for ABB robots

Figure 3: Sumoflex Dresspack on the spot-welding robot

More freedom of movement thanks to Sumotex

It’s not only the robot that determines the motion of its axes, but also the cable management system. Cable loops or whipping cable bundles can quickly limit flexibility. To ensure that the IRB 6750S can show its full potential in handling, it was therefore equipped with Sumotex from Sumcab Robotics. The special hose design with inherent restoring force ensures that the robot’s wrist axis remains unobstructed—without disruptive cable loops.

This brings several advantages for the application:

- Maximum freedom of movement, especially in tight plant layouts

- Reduced collision risk thanks to the compact Dresspack

- More stable processes through less strain on cables and connectors

The IRB 6750S is designed for flexibility and speed in narrow production cells. In combination with Sumotex, it provides a particularly efficient and space-saving robot

solution, as demanded in the automotive and supplier industries.

For the additional spot welding robot shown, however, Sumotex was not used—instead, the Sumoflex system was applied, since in this case the Dresspack’s diameter plays a central role. With its retraction carriage and open design, the Sumoflex system is better suited here and is a good example of how important a specialized provider of cable management systems is for achieving an optimal solution.

Two technology leaders – one well-thought-out solution

Due to the wide variety of industry-specific requirements, creating customized Dresspacks for established robot manufacturers is often a challenge.

That’s why ABB specifically relies on collaboration with specialized providers such as Sumcab. When two experts combine their respective strengths—ABB in robotics and Sumcab in application-specific Dresspacks, the result is a solution that not only works technically but is also tailored to real production conditions.

The outcome is a coordinated overall system that enables more freedom of movement, increases process reliability, and at the same time simplifies commissioning and maintenance.

Customers benefit not only from technical innovations but above all from a holistic solution tailored to real production requirements.

The combination of ABB robotics and Sumotex Dresspacks sets new standards in heavy-duty handling—a strong signal for future-proof automation solutions.

Figure 4: Sumotex and Sumoflex – two solutions for different robotic applications

Conclusion: Innovation and collaboration as drivers of customer success

The cooperation between ABB and Sumcab demonstrates how collaboration along the entire value chain can create practical, maintenance-friendly, and durable robotic solutions.